What Should You Know Before Buying an Underpad Machine?

2025-08-12

Underpads—also called bed pads or chux—are essential in hospitals, nursing homes, pet care facilities, and even home healthcare in the U.S. With demand rising, many manufacturers are now looking to invest in underpad production machines.

But before you sign that purchase order, here’s what you should know.

Step 1: Understand Your Target Market

Are you producing underpads for:

-

Medical use (hospitals, nursing homes)

-

Pet training pads (dogs, cats)

-

Home healthcare (elderly care)

The answer will determine your machine’s capacity, absorbent core size, and packaging options.

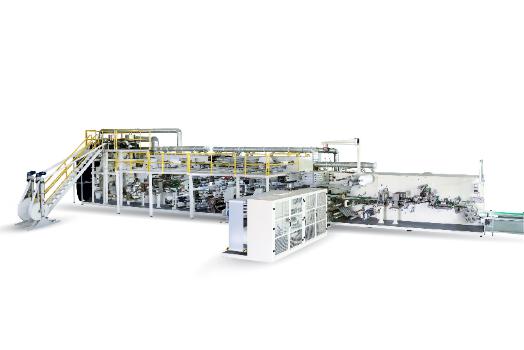

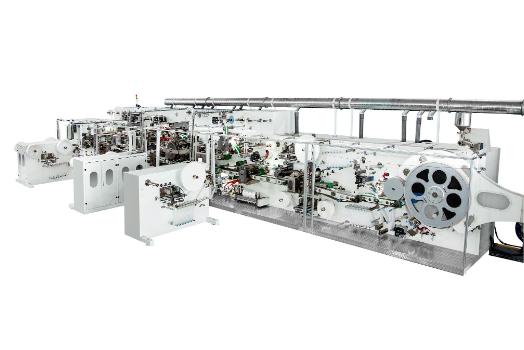

Step 2: Choose the Right Machine Configuration

Modern underpad machines come in different setups:

-

Full Servo Systems: Maximum automation, minimal human error, highest speed.

-

Semi Servo Systems: Lower cost, still efficient, great for small to mid-size factories.

Don’t forget to check the machine’s compatibility with U.S. power standards. Yes, it’s a big deal—otherwise, you’re paying extra for conversion.

Step 3: Factor in Hidden Costs

Price tags can be deceiving. Besides the machine cost, you’ll also need to budget for:

-

Raw material supply chain setup

-

Installation & training

-

Shipping & import duties

-

Spare parts & maintenance

At Shengquan Machinery, we tell our customers up front—no surprise fees later. Because who likes that? Nobody.

Step 4: Look for Multi-Function Capability

Some underpad machines can also produce pet pads with small adjustments. That means one investment, two revenue streams. That’s a win-win if you ask me.

Buying an underpad machine is a major investment, but with the right supplier, it’s also a profitable move. The U.S. market for disposable underpads is strong, and demand shows no sign of slowing.

If you want a reliable, high-speed, U.S.-compliant underpad production line, Shengquan Machinery is ready to help you every step of the way.