Shengquan Leading Diaper Machine Innovation

2025-06-04

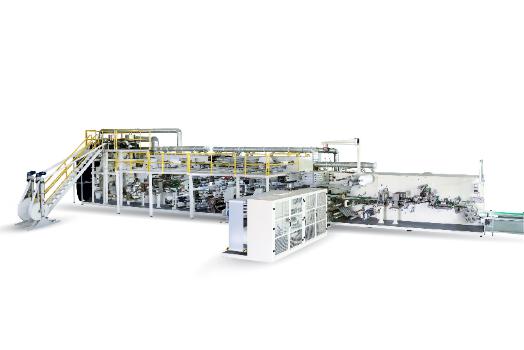

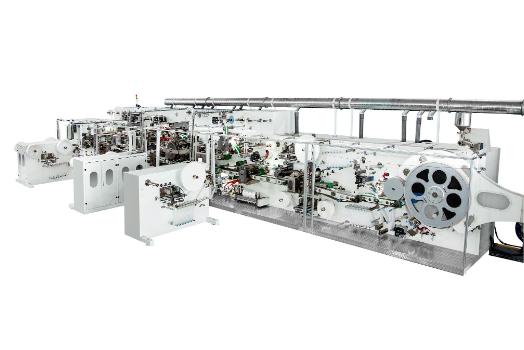

In the fast-evolving hygiene product industry, efficiency, precision, and scalability are essential for success—and Shengquan, a leading diaper manufacturing equipment manufacturer based in China, has emerged as a trusted name for high-performance machinery. Specializing in the I shape diaper machine and full baby diaper production line systems, Shengquan offers advanced automation, reliability, and tailored engineering that meets global standards.

Engineering Excellence in Diaper Production

At the core of Shengquan’s reputation is its innovative approach to diaper manufacturing technology. The I shape diaper machine, one of Shengquan’s flagship products, is designed to produce high-quality baby and adult diapers with superior consistency and speed. This machine integrates cutting-edge servo control, ultrasonic bonding, and intelligent PLC systems to ensure precise material handling, minimal waste, and optimal output.

Capable of producing thousands of diapers per minute, the I shape diaper machine from Shengquan supports manufacturers in meeting large-scale demand while maintaining product integrity and comfort. Whether for disposable baby diapers or premium eco-friendly lines, this equipment delivers unmatched performance.

Made in China – Trusted Worldwide

As a top-tier manufacturer from China, Shengquan combines local expertise with international quality standards. Its modern facilities are equipped with CNC machining centers, robotic assembly lines, and comprehensive testing labs to ensure every component meets rigorous durability and safety benchmarks.

This commitment to excellence has earned Shengquan recognition across North America, Europe, Southeast Asia, Africa, and the Middle East. With a focus on innovation and customer satisfaction, Shengquan continues to be a go-to partner for companies looking to enter or expand within the hygiene product market.

Custom Solutions for Unique Needs

What sets Shengquan apart from other wholesale diaper machine suppliers is its strong emphasis on custom engineering. Understanding that no two production needs are the same, the brand offers tailored configurations for its baby diaper production line, including adjustments for product size, material compatibility, packaging options, and output capacity.

Whether a client requires a compact semi-automatic system or a fully automated I shape diaper machine, Shengquan works closely with them to design a solution that aligns with their business goals, budget, and target market demands.

Comprehensive Baby Diaper Production Line Integration

Beyond individual machines, Shengquan provides end-to-end baby diaper production line integration. From raw material feeding and core forming to cutting, folding, packing, and labeling—each stage is seamlessly connected to maximize productivity and reduce manual labor.

The production lines are compatible with various diaper types, including pant-style, pad-style, and training pants, making them versatile for different consumer segments. Additionally, Shengquan offers after-sales support, including installation guidance, operator training, and spare parts supply—ensuring smooth operation from day one.

Sustainability and Smart Manufacturing

In response to growing environmental awareness, Shengquan incorporates energy-efficient components and low-waste processing technologies into its machines. These innovations help reduce power consumption, minimize material loss, and support sustainable production practices.

Furthermore, the brand is actively investing in smart manufacturing solutions, such as IoT-enabled monitoring systems and predictive maintenance features, to enhance machine uptime and operational efficiency for clients.

A Global Wholesale Partner

Beyond being a premier diaper manufacturing equipment manufacturer, Shengquan operates as a professional wholesale diaper machine supplier, offering scalable solutions for distributors, private-label brands, and new entrants into the hygiene industry.

With streamlined logistics, competitive pricing, and multilingual customer support, Shengquan ensures timely delivery and seamless integration into global markets. Clients benefit from flexible MOQs, OEM branding options, and dedicated technical consultation throughout the purchasing process.

In conclusion, Shengquan leads the way as a top I shape diaper machine manufacturer in China, delivering high-performance baby diaper production lines, diaper manufacturing equipment, and custom engineering solutions tailored to diverse business needs.

As a trusted wholesale diaper machine supplier, Shengquan empowers entrepreneurs and established brands alike with the tools they need to succeed in the competitive hygiene industry—combining innovation, quality, and personalized service to drive long-term growth.

By choosing Shengquan, you're not only investing in world-class machinery—you're partnering with a brand committed to your production success through precision, reliability, and forward-thinking technology.