How to Choose the Right Baby Diaper Machine for Your Manufacturing Business

2025-07-17

If you're planning to start or expand a diaper production line, choosing the right baby diaper machine is the most crucial step. With growing demand in the U.S. for high-quality disposable diapers, manufacturers are under pressure to deliver faster, better, and at lower cost. That’s exactly where an advanced baby diaper production machine comes into play.

But with so many diaper machine suppliers on the market, especially in China, how do you pick the best one?

Let’s walk you through everything you need to know before making this important decision.

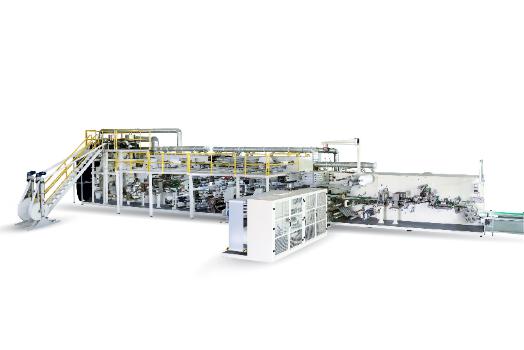

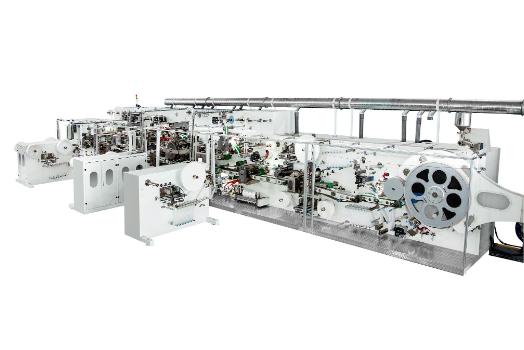

What Is a Baby Diaper Machine?

A baby diaper machine is an automated production line that converts raw materials into finished baby diapers. From fluff pulp and SAP layers to elastic leg cuffs and frontal tapes, this machine assembles all parts into a neatly folded and packaged diaper—ready for retail.

Depending on your budget and production goals, there are different types of machines available:

Full Servo Baby Diaper Machine

Semi-servo Diaper Machine

Economic Diaper Line for Small Scale Production

High-Speed Baby Diaper Machine (600-800 pcs/min)

Some machines also include inline packaging units, stacking functions, and product inspection systems.

Key Features to Look For

When evaluating baby diaper machinery, it’s not just about speed. Here are some features that U.S. buyers should care about:

1. Automation Level

A full servo system minimizes manual operation and increases consistency. While the price might be higher upfront, it reduces long-term labor costs and errors.

2. Product Size Flexibility

Can the machine switch between sizes like NB, S, M, L, XL? This matters a lot if your brand covers multiple age groups.

3. Raw Material Compatibility

Check whether the diaper machine supports both traditional and biodegradable materials. With the rising trend in eco-friendly diapers, this could be a game-changer for your brand.

4. Technical Support and After-Sales Service

Even the best machine needs occasional maintenance. Choose a baby diaper machine supplier that offers remote troubleshooting and spare parts support—even better if they got English-speaking technicians.

Why Buy From a China Manufacturer?

You might be wondering, “Why should I source from China?” Well, let me break it down for you:

Competitive pricing without sacrificing quality

Mature supply chain for spare parts and raw materials

Customizable design for your unique product specs

Strong R&D to support innovation and automation

Our company has been serving American diaper brands for years, and we knows how to tailor the machine to your packaging and performance needs.

Common Concerns from U.S. Buyers (and How We Solve Them)

1. Shipping & Logistics

No worries—our team handles sea freight, customs clearance documents (FDA, CE), and even helps you plan the factory layout.

2. Machine Installation & Training

We offer on-site engineer dispatch (or video guidance during COVID times). Your team will be trained within a few days.

3. Warranty & After-sale Support

Our baby diaper machines come with a 12-month warranty, plus lifetime technical support. If something breaks, we don’t just leave you hanging.

Final Words

Investing in the right baby diaper machine can make or break your production success. Whether you’re a startup brand in California or a large manufacturer in Texas, you need equipment that’s efficient, reliable, and easy to maintain. As a China-based baby diaper machine manufacturer and supplier, we understand your concerns—and we’re here to make things easy.

Need help figuring out the right model? Let’s talk. We’ll guide you every step of the way.