Shengquan: Precision Diaper Machines from China

2025-04-25

In the fiercely competitive world of hygiene manufacturing, where efficiency and innovation dictate market dominance, Shengquan has emerged as a trailblazer among China’s machinery manufacturers. Specializing in full servo pull-up baby diaper machines, high-speed baby diaper machines for sale, and pull-up training pants production systems, the brand combines German-engineered precision with Chinese manufacturing agility to empower global diaper producers.

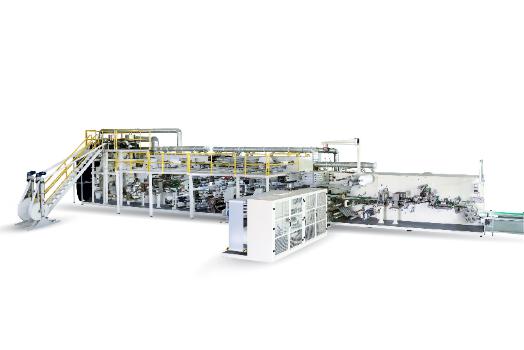

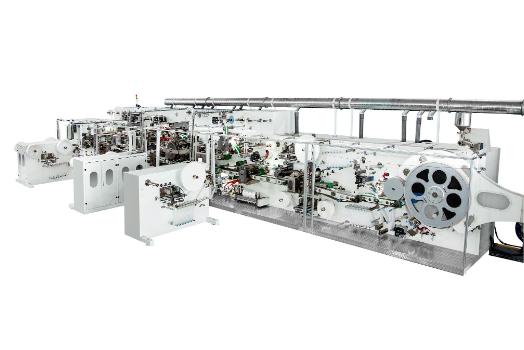

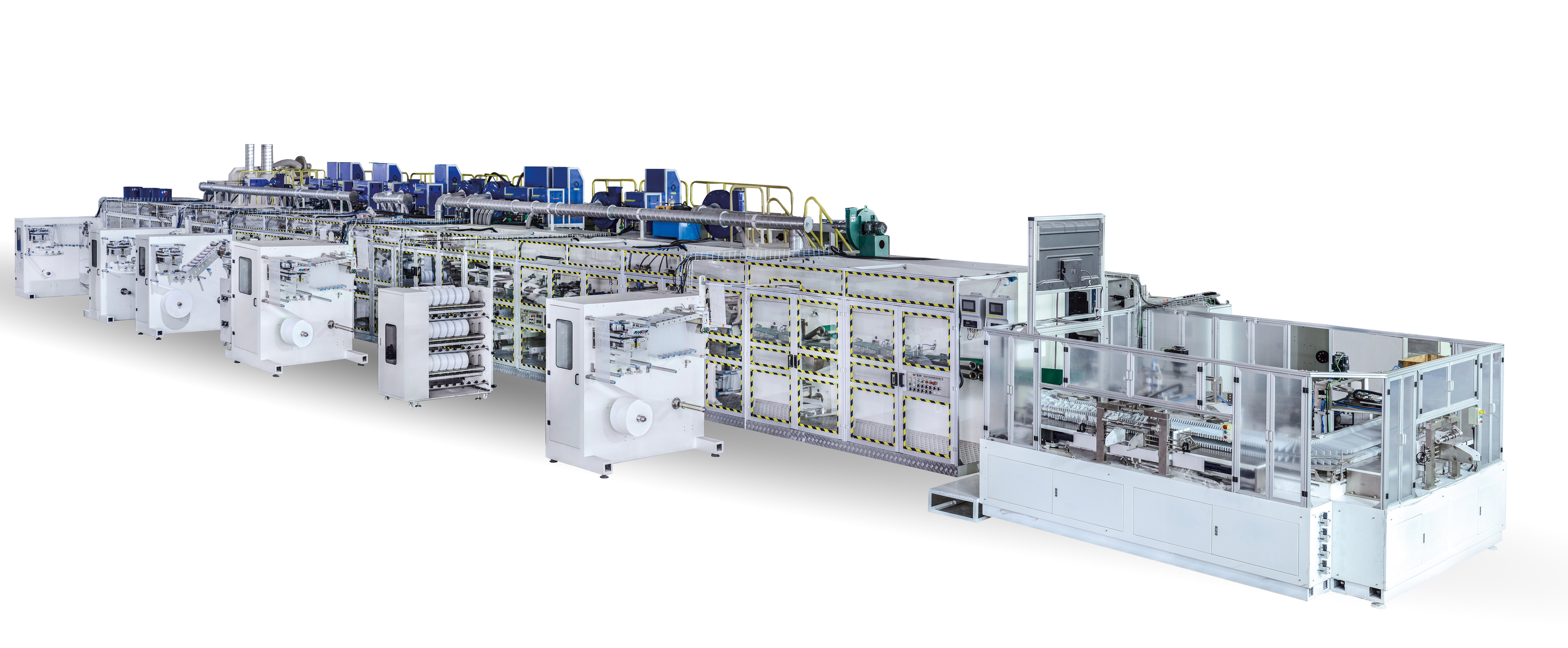

At the core of Shengquan’s portfolio lies its full servo pull-up baby diaper machine—a marvel of automation designed for 24/7 reliability. Unlike conventional hydraulic systems, this machine employs servo-driven technology to synchronize 12+ production stations with microsecond accuracy, ensuring zero-defect diapers at speeds of up to 800 pieces per minute. Key features include AI-powered elastic waistband calibration, 3D-contoured leg cuff welding, and a self-cleaning adhesive application system that reduces material waste by 15%. For brands seeking custom pull-up training pants machines, Shengquan’s engineers integrate modular components—such as adjustable side-panel attachers or reusable underwear-style fastening units—to meet regional market preferences.

The brand’s high-speed baby diaper machines for sale redefine industry benchmarks. Engineered for Tier 1 manufacturers, these behemoths boast a 2.2-meter-wide production web, enabling simultaneous output of newborn to toddler sizes. Shengquan’s proprietary “TurboFlow” system accelerates core formation by 30%, while a dual-layer SAP (superabsorbent polymer) dispenser ensures uniform distribution—critical for premium products. Clients, from Southeast Asian ODMs to European private-label giants, praise the machines’ intuitive HMI touchscreens, which allow real-time adjustments to lotion application, backsheet patterns, or wetness indicator placement without halting production.

For businesses launching pull-up diaper production lines, Shengquan acts as a strategic partner, not just a supplier. The brand’s China-based R&D hub offers custom machinery solutions tailored to niche demands. A Middle Eastern client, for instance, commissioned a machine with integrated aloe-infused topsheet coating to combat regional humidity, while a Latin American manufacturer opted for a biodegradable film-laminating module to align with eco-conscious consumer trends. Shengquan’s turnkey packages include factory layout design, operator training, and a 24/7 remote diagnostics platform, minimizing downtime for global clients.

China’s Manufacturing Edge:

Shengquan leverages China’s unparalleled supply chain to deliver cost-effective excellence. Core components—such as Japanese-made Mitsubishi servo motors or Swiss-engineered ultrasonic welding heads—are sourced locally through tier-1 partnerships, ensuring quality without premium markups. The brand’s 150,000-sqm factory in Fujian Province houses a vertical integration ecosystem, from steel cutting to software coding, enabling rapid prototyping of custom pull-up diaper production machines. A recent collaboration with a U.S. startup saw a prototype-to-production timeline slashed from 6 months to 10 weeks.

Sustainability is woven into Shengquan’s machinery DNA. Its “EcoDrive” line of machines reduces energy consumption by 22% via regenerative braking systems, while a closed-loop water filtration unit slashes factory wastewater by 90%. For brands targeting circular economies, Shengquan offers recyclable diaper production modules that separate backsheets, cores, and elastics for downstream sorting—a game-changer for compliance with EU Single-Use Plastics Directives.

Why Partner with Shengquan?

China-Made Precision: 20+ years of honing servo-driven machinery for global hygiene leaders.

Customization Mastery: From pull-up diaper machines to training pants lines, every parameter is adaptable.

Scalable Excellence: Machines built to grow with your business—whether you produce 1 million or 1 billion diapers annually.

In an industry where milliseconds and millimeters separate success from stagnation, Shengquan equips manufacturers with the tools to lead. By blending China’s manufacturing might with bespoke engineering, the brand isn’t just selling machines—it’s investing in its clients’ futures.

For a free consultation or to tour Shengquan’s innovation center in China, contact the team today. Discover how custom machinery can transform your diaper production into a competitive advantage.