Advanced Diaper Manufacturing Solutions

2025-05-09

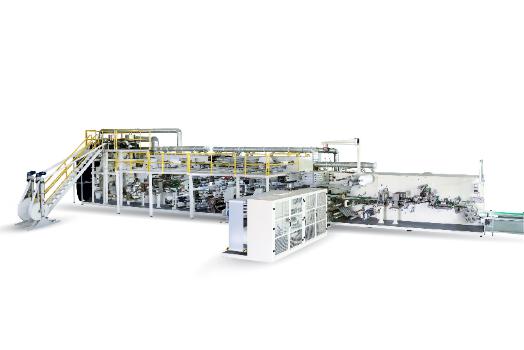

In the fast-evolving hygiene product industry, efficiency, automation, and scalability are crucial for maintaining competitiveness — especially when it comes to baby care essentials like diapers. Among the most advanced production systems available today is the T-shape baby diaper machine, a high-speed, fully integrated solution designed for large-scale manufacturing.

As a leading provider of intelligent hygiene equipment, Shengquan delivers cutting-edge full servo diaper production lines that combine precision engineering with smart automation. By collaborating closely with experienced manufacturers in China, Shengquan ensures every machine meets global quality standards while offering custom configurations tailored to specific production needs.

Whether you're setting up a new factory or upgrading an existing line, Shengquan provides reliable, scalable, and cost-effective baby diaper machine for factory use, as well as comprehensive support for turnkey operations.

The Innovation Behind T-Shape Baby Diaper Machines

The T-shape baby diaper machine represents the pinnacle of modern diaper manufacturing technology. Unlike older models that rely on mechanical components and manual adjustments, this system integrates full servo control, allowing for precise motion regulation, faster cycle times, and improved consistency across all stages of production.

Key features of the T-shape baby diaper machine include:

High-speed operation – Capable of producing up to 600 pieces per minute

Modular design – Easy to upgrade and maintain based on evolving needs

Fully automated process – From web feeding and core forming to cutting, folding, and packaging

Smart diagnostics – Real-time monitoring and error detection via touchscreen interface

At Shengquan, each T-shape machine is engineered using premium-grade components and built-in safety protocols to ensure long-term durability and operator protection. These systems are ideal for both domestic and international manufacturers looking to boost productivity without compromising on quality.

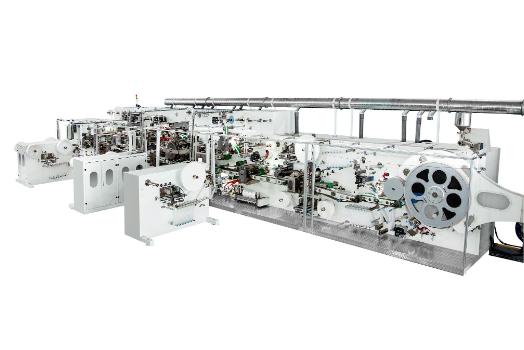

Full Servo Diaper Production Line – Efficiency Redefined

For factories aiming to achieve maximum output with minimal labor input, the full servo diaper production line offered by Shengquan is the optimal choice. This complete system includes:

Core assembly units (absorbent pad, SAP insertion)

Outer cover forming stations

Elastic attachment modules

Leak guard shaping and bonding units

Final cutting, folding, and packaging integration

All components operate under synchronized servo control, ensuring seamless coordination between each stage and minimizing material waste. Additionally, the system supports multiple product formats — including pant-style and standard diapers — making it highly adaptable for various market demands.

Shengquan’s full servo diaper production line is widely used by manufacturers across Southeast Asia, Africa, the Middle East, and Latin America due to its proven performance and ease of integration into existing facilities.

Custom Diaper Manufacturing Equipment for Global Brands

Beyond standard solutions, Shengquan also specializes in providing custom diaper manufacturing equipment tailored to meet specific brand requirements. Whether you're launching a niche eco-friendly line or require specialized machinery for biodegradable materials, Shengquan’s R&D team can adapt the machine layout, control system, and even software interface to match your vision.

Our customization services include:

Customized machine dimensions and layout

Material compatibility upgrades (e.g., non-woven fabrics, organic cotton)

Language-specific HMI panels and training manuals

Private labeling and OEM branding options

This flexibility makes Shengquan a preferred partner for entrepreneurs, startups, and established brands entering or expanding within the hygiene product sector.

Why Choose Shengquan?

Choosing Shengquan means choosing a trusted name backed by years of technical expertise and a strong network of certified manufacturers in China. Here's why we stand out:

Proven experience in designing and delivering T-shape baby diaper machines

Strong partnerships with top-tier China-based manufacturers specializing in automation and hygienic equipment

Comprehensive custom machine development and after-sales service

Competitive pricing and wholesale supply of diaper manufacturing equipment

With increasing demand for high-performance, sustainable, and cost-efficient diaper production lines, Shengquan continues to lead the way in innovation and reliability.

From T-shape baby diaper machines to custom OEM solutions, Shengquan stands at the forefront of modern hygiene manufacturing technology. By working closely with expert manufacturers in China, the brand delivers intelligent, scalable, and future-ready production systems that empower businesses worldwide.

Whether you’re starting a new diaper factory, expanding capacity, or looking to enhance your current setup, Shengquan offers the tools, expertise, and support needed to succeed — one diaper line at a time.