What Makes a Sanitary Pad Soft and Absorbent?

2025-08-19

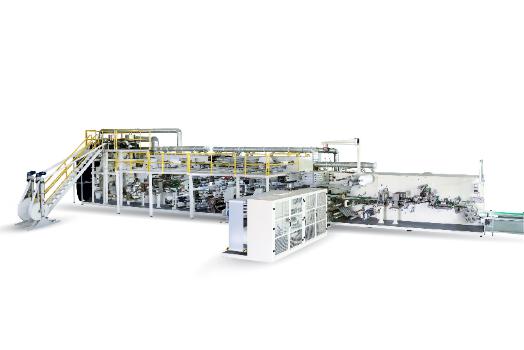

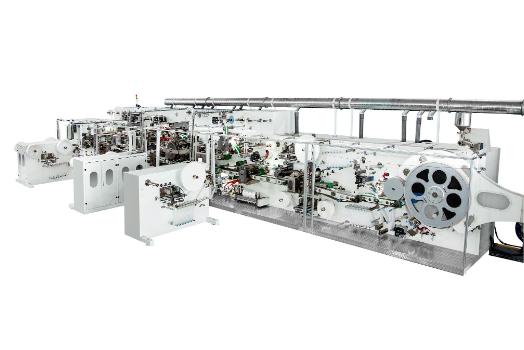

Ever wondered why some sanitary pads feel so soft and absorb so well, while others are… well, less comfy? A lot of it comes down to how they’re made and the sanitary pad machines that produce them. Today, we’re diving into the process and sharing some insider knowledge.

Step 1: Choosing the Right Materials

The first secret is the materials. Modern sanitary pads use a combination of soft topsheets, absorbent cores (often containing SAP), and breathable backsheets. The right blend ensures that the pad can hold liquid efficiently while feeling gentle on skin.

Machines layer these materials precisely. Even a tiny misalignment can affect comfort or absorption, so precision is key.

Step 2: Designing for Comfort

Sanitary pad machines don’t just stick layers together—they shape them. Pads may have wings, contoured edges, or extra absorbent zones in the center. The machine cuts and folds the materials accurately so the pad fits the body comfortably and stays in place.

This is also where you get thin yet highly absorbent pads. Thanks to advanced machine calibration, even ultra-thin pads won’t leak—pretty impressive, huh?

Step 3: Adding Softness Without Compromising Strength

A pad needs to feel soft but still strong. Machines use ultrasonic bonding or adhesives to attach layers, balancing softness with durability. This ensures the pad won’t tear, bunch up, or lose absorption, even when active.

Some machines even allow adjustable thickness for day vs night pads—so production can match different user needs without buying a whole new line.

Step 4: Inspection and Packaging

Finally, pads go through a quality inspection stage. Machines check for correct alignment, secure bonding, and consistent weight. After passing inspection, pads are stacked and packaged neatly for store shelves.

This automated process means users get a consistent, comfortable product every time. And honestly, it’s pretty cool to see machines making something so important for daily life.

Sanitary pad machines may be hidden in factories, but they play a big role in comfort and reliability. Next time you pick up a pad, you can appreciate the careful engineering and technology behind every single piece.