How Much Does It Cost to Set Up a Baby Diaper Production Line in 2025?

2025-08-05

If you're planning to enter the baby care industry in the United States, starting your own baby diaper production line is one of the most promising opportunities in 2025. But here comes the big question for most investors and manufacturers:

👉 How much does it actually cost to set up a baby diaper machine and a complete production line?

In this article, we'll break down the typical investment range, what's included in the cost, and how to make smart decisions when sourcing from China.

Why the Baby Diaper Market Still Booms in the U.S.

Despite inflation and changing consumer trends, the U.S. baby diaper market is projected to grow steadily in the coming years. That’s thanks to:

-

Stable birth rates in certain states

-

High demand for premium & eco-friendly diapers

-

E-commerce brands launching private labels

-

Hospitals and clinics expanding disposable use

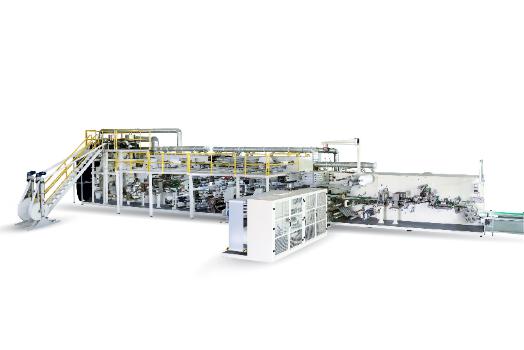

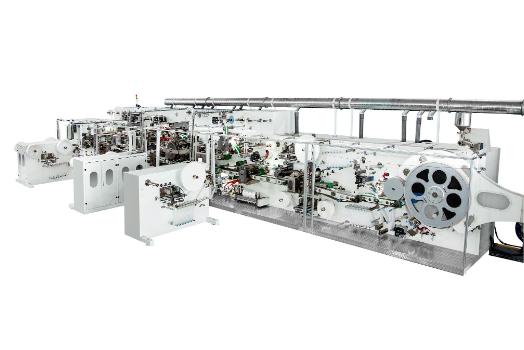

Whether you're a startup brand or a contract manufacturer, getting the right baby diaper machine is key to ensuring efficiency and profitability.

So… What Goes Into the Total Cost?

When people ask us, "How much is the baby diaper machine?"—the truth is, it depends. A lot.

Here's what usually makes up the cost:

| Item | Estimated Range (USD) |

|---|---|

| Baby Diaper Machine (Semi Servo) | $150,000 – $250,000 |

| Baby Diaper Machine (Full Servo) | $280,000 – $600,000 |

| Air Compressor & Glue Applicator | $20,000 – $50,000 |

| Stacking & Packaging Line | $30,000 – $100,000 |

| Shipping & Import Duties | $15,000 – $40,000 |

| Installation + Technical Support | $10,000 – $30,000 |

👉 Total Setup Cost: Usually between $250,000 – $900,000+, depending on your configuration.

Should You Start with Full-Servo Machines?

Well, it depends on your budget and your volume. Full-servo machines are awesome—they're fast, precise, and reduce waste. But they do cost more upfront.

For startups or low-volume factories, semi-servo baby diaper machines can be a smart entry point. They’re easier to operate and offer high flexibility.

And honestly? You can always upgrade modules later. You're not stuck with one setup forever.

What Hidden Costs Should You Watch For?

Some suppliers don't tell you everything upfront, but here’s what you should ask about:

-

Electrical configuration (some are 380V, but U.S. uses 220V/480V)

-

Training duration and number of technicians

-

After-sales support & warranty terms

-

Spare parts availability in your country

At Shengquan Machinery, we provide U.S.-compliant configurations, English-language HMI, and a full-service technical support plan—because yeah, nobody wants surprise costs later.

So, Is It Worth It?

Let’s face it: buying a baby diaper machine isn’t cheap. But if you pick the right supplier and machine model, you’ll set yourself up for long-term profits and brand growth.

Plus, with strong demand in both retail and institutional markets, ROI can come quicker than you think.

Starting a baby diaper production line in the U.S. is a big step—but one with huge potential. Whether you're launching a new brand or localizing production, Shengquan Machinery is here to help with expert advice, advanced equipment, and full U.S. export experience.

Wanna know if your budget fits? Just ask us.