How to Start a Baby Diaper Production Line with Minimal Investment

2025-07-23

Entering the baby care industry in the U.S. may sound expensive, but guess what? Setting up a baby diaper production line doesn't have to break the bank—if you choose the right equipment and supplier. With more private-label hygiene brands popping up, American entrepreneurs are actively looking for affordable baby diaper machines that still meet high standards.

At Quanzhou Shengquan Machinery Co., Ltd, we help startups and medium-sized manufacturers launch diaper production with lower capital but higher output.

Is a Baby Diaper Production Line Really Affordable?

Many new business owners assume that starting a baby diaper manufacturing line costs millions. But that’s not always true. With the right layout and smart equipment selection, you can begin production with a fraction of the expected cost.

Here’s how we help you minimize your investment:

-

Semi-servo baby diaper machine: Lower cost, stable performance

-

Compact line designs: Save space and energy

-

Quick mold-switching features: Reduce downtime and startup loss

-

Modular automation: Upgrade only when needed

You ain't need the most expensive gear to make high-quality diapers. You just need the right setup.

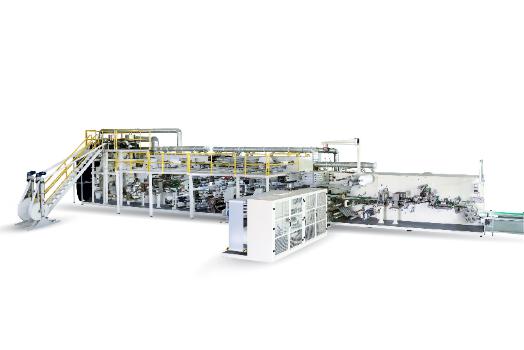

Key Machines Needed for a Diaper Production Line

A basic baby diaper production line usually includes the following core equipment:

-

Baby Diaper Machine – The main machine that assembles all components

-

Packing Machine – Wraps and seals the finished diapers

-

Stacker & Conveyor – Organizes and moves products through the process

-

Air Compressors & Glue Systems – Powers adhesion and forming

At Shengquan, we provide integrated systems that can be installed step-by-step, giving you full control of your budget.

Choosing the Right Supplier: Why China?

Now let’s talk suppliers. You might be wondering—why are so many U.S. businesses sourcing baby diaper machines from China?

Simple:

-

Cost Advantage: Machines are 40-60% cheaper than those from Europe or Japan

-

Strong Manufacturing Base: Factories like Shengquan offer proven solutions with CE and ISO standards

-

Customization: Machines are designed for American packaging styles and size preferences

-

Fast Shipping & Remote Support: Even from overseas, we keep your line running smoothly

We’ve already helped dozens of U.S. companies get their diaper factories up and running, sometimes in just 45 days.

Technical Support: You’re Never On Your Own

We know that launching a new production line can be scary—especially if you're new to manufacturing. That’s why our support doesn’t end after delivery.

Our team offers:

-

Virtual training in English

-

Remote troubleshooting (VPN diagnostics)

-

On-site engineers upon request

-

Quick-delivery spare parts from our Chinese warehouse

Honestly, we treat your production like it’s our own.

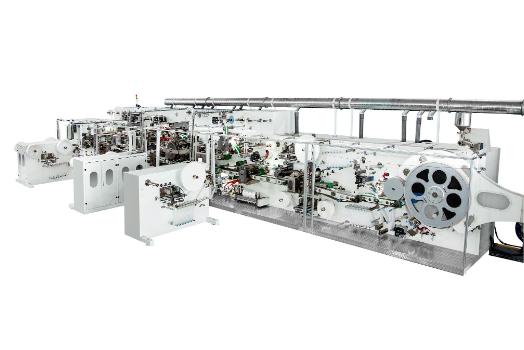

Start Small, Scale Fast

You don’t need to build a giant factory on day one. Our most popular entry-level baby diaper machine models are ideal for:

-

Startup hygiene brands

-

Regional private-label factories

-

Medical and retail supply distributors

Later on, you can upgrade to a full-servo system or expand to adult diaper, sanitary pad, or underpad production using the same supplier and support system.

Ready to Launch Your Own Baby Diaper Line?

Starting a baby diaper production line in the U.S. has never been more accessible. With Shengquan Machinery’s cost-effective solutions and hands-on support, you can turn your business idea into reality—without massive upfront costs.

If you're looking for a China baby diaper machine manufacturer that understands American standards and business timelines, we’re here to help. Let’s talk investment plans, factory layout, and machine selection today.

You just focus on growing your brand—we’ll take care of the rest.