Can One Sanitary Pad Machine Produce Multiple Types of Pads?

2025-08-05

This is a question we get all the time from U.S. hygiene product manufacturers:

"Do I need to buy separate machines for each type of sanitary pad?"

The short answer?

No—you don't.

Thanks to new tech in modular sanitary pad machines, one line can now handle multiple product formats with minimal changeover time.

Let’s dive into how it works, what it means for your business, and why this flexibility is a game changer.

What Types of Pads Can One Machine Handle?

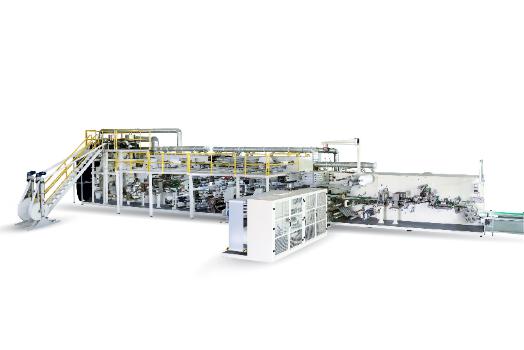

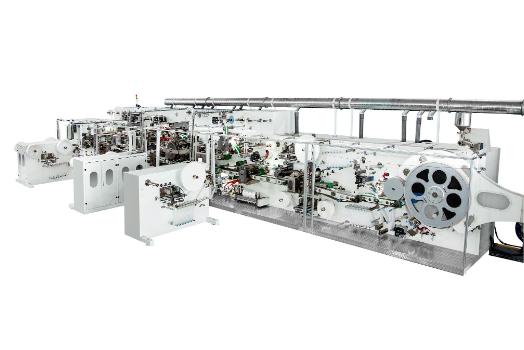

Modern sanitary napkin machines, like the ones manufactured by Shengquan Machinery, are capable of producing:

-

Day Use Pads

-

Night Use Pads

-

Panty Liners

-

Ultra-Thin Sanitary Pads

-

Winged and Non-Winged Pads

Some machines even support organic pad production with biodegradable topsheets.

How Does Switching Between Pad Types Work?

Here’s the cool part:

With a modular machine layout, operators can switch pad size and style using preset programs and part adjustments. Depending on the machine, changeover can take:

⏱️ 15–60 minutes, depending on the size shift and configuration.

It’s not 100% plug-and-play—but it’s way faster and cheaper than owning multiple production lines.

Advantages of Multi-Function Sanitary Pad Machines

Here’s why American manufacturers are loving this:

-

Save factory space 🏭

-

Cut down on equipment investment 💰

-

Respond faster to market trends 🔄

-

Support small-batch, private label production 💡

Honestly, if you’re starting with limited capital or space, going multifunction is a no-brainer.

What to Watch Out For

However, not all "multi-format" machines are equal. When sourcing from China, ask about:

-

Material tolerance

-

Adhesive application precision

-

Waste handling system

-

Servo control vs mechanical drive

-

Real-time monitoring & alarms

At Shengquan Machinery, we design sanitary pad machines with servo-based precision and U.S.-market packaging specs in mind.

Yes, we helps you meet those tough quality checks 😉

So yes, one sanitary pad machine can absolutely produce multiple styles of pads—as long as you choose the right equipment and supplier.

If you're looking to stay flexible, lower costs, and build a nimble production setup, a multifunction machine is your best bet.